Industry 4.0 is the fourth industrial revolution, characterized by a shift to automation and data sharing in manufacturing technologies.

Globally, there is a surge in demand for advanced digital solutions that enable manufacturers to maximize productivity and reduce costs. Countries around the world are investing heavily in research and development of new technologies such as artificial intelligence, robotics, 3D printing, the Internet of Things (IoT) and autonomous systems. This has led to an increase in global optimization of production lines, as well as improved supply chain management.

Additionally, Industry 4.0 has enabled companies to improve customer service and satisfaction through faster delivery times and better product customization. While there is still a lot of work to be done to implement Industry 4.0 solutions in all industries around the world, it is clear that countries are embracing the potential benefits of this new industrial revolution.

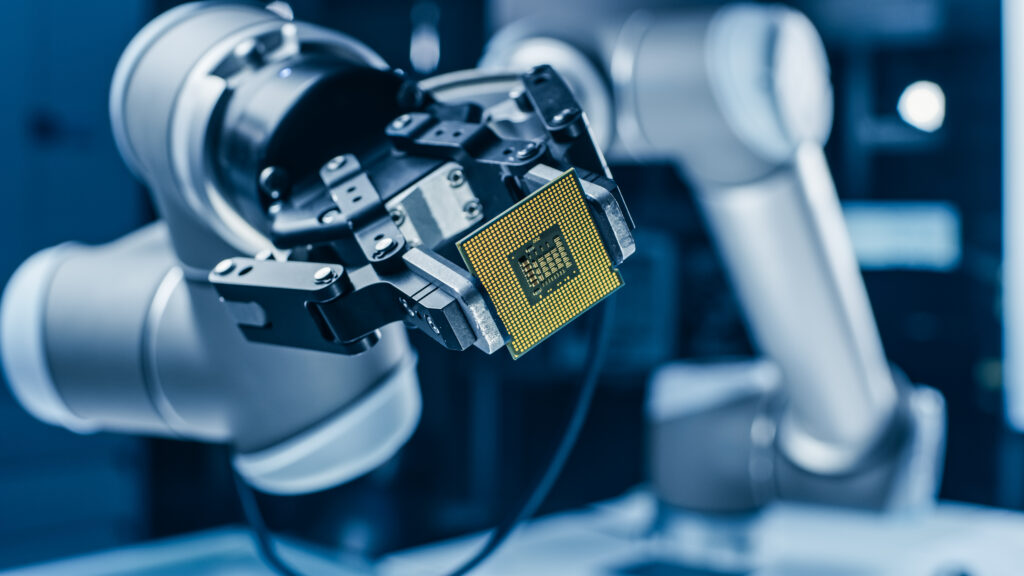

Process robotization is gearing up for a technical revolution

Process robotization is gearing up for a technical revolution that will significantly change the way we live and work. The technology is being used to automate tedious, labor-intensive tasks such as manufacturing, data processing and customer service. By replacing humans with robots, companies can cut costs while increasing productivity and accuracy.

Automation also allows companies to increase efficiency and reduce production time. Thanks to advances in artificial intelligence and machine learning, robots are increasingly capable of learning from experience and performing complex tasks with minimal human input.

This means that the robotization of processes will enable companies to increase both production and service efficiency, which is expected to translate into increased financial returns as well. As the technology becomes more widespread in the coming years, it promises to usher in an era of unprecedented technological development.

Industry 4.0 – how to optimize production on many levels?

Automation can be used to monitor production processes, identify potential problems early and adapt to them quickly. AI-powered predictive analytics can help manufacturers anticipate and respond to changing market demands in real time.

Additionally, Big Data and IoT can provide real-time insights into supply chain issues so that timely decisions can be made to improve productivity and reduce waste. All of these advances are helping companies approach a changing environment more flexibly, and in turn, become more competitive in today’s global economy.

Man in Industry 4.0

Man in Industry 4.0 is a figure that has taken center stage in the digital transformation of modern industry. It is characterized by the use of advanced technologies such as artificial intelligence, robotics, big data and cloud computing to automate processes, increase productivity and accuracy, and develop new products and services.

Why? Because it is humans and their ability to think logically, adapt, and innovate that have led to improvements in manufacturing and production processes that could translate into total industry automation.

Man will therefore be an integral part of the success of companies that decide to move toward Industry 4.0. He will spearhead the introduction of a revolution in industrial operations that will benefit all parties involved and introduce new, unprecedented levels of efficiency, speed, quality assurance and cost-effectiveness.

Industry 4.0 – summary

Industry 4.0 is the fourth industrial revolution, driven by digital technologies such as artificial intelligence, machine learning, the Internet of Things, 3D printing and cloud computing. It promises to radically change the way businesses operate, with greater efficiency, flexibility and speed.

This new wave of technology will also provide companies with more opportunities to collaborate with customers and suppliers to develop innovative products or services. All these advances are expected to result in improved customer service, increased productivity and cost savings for businesses.