About the Company

Horus-Energia Sp. z o.o. has been actively participating in the energy transition in both domestic and international markets for 40 years. From the very beginning, we have been at the forefront of implementing innovative and pioneering solutions. In recent years, in line with current market trends, we have focused on low-emission and zero-emission energy production and efficiency maximization.

Spectrum of Fuels

The domestic market has seen significant changes in the types of fuels used for energy generation. A decade ago, hydrogen was more of an issue and a byproduct in manufacturing processes rather than a desirable fuel of the future. Our first hydrogen project took place between 2012 and 2014 at the Kędzierzyn Chemical Plant (ZAK). In the production process, a waste gas with a hydrogen content of 85-95% was generated, with no direct use for it. Our three cogeneration units, with a total capacity of 1MW, enabled this byproduct to be used to produce heat combined with electricity for the plant’s needs. In this way, the waste gas was utilized beneficially, bringing tangible energy benefits to ZAK. Our teams worked over 40,000 hours at ZAK, and the operational experience gained was a valuable source of information that allowed us to further develop our technology.

In various R&D projects, in collaboration with leading Polish academic centers, we developed and then commercially launched products that allow the use of different types of fuels previously considered as byproducts. For example, we are working on a project where the fuel is gas produced from the gasification of sewage sludge, co-combusted with biogas generated in the same treatment plant. Another example is the gasification of biomass, such as production residues in sawmills or furniture and carpentry companies. This refers, of course, to pure wood material (offcuts, chips, bark, sawdust) without contaminants like adhesives, varnishes, or other substances. This approach not only manages production residues without classifying and disposing of them as waste but also reduces the plant’s need to purchase electricity or heat.

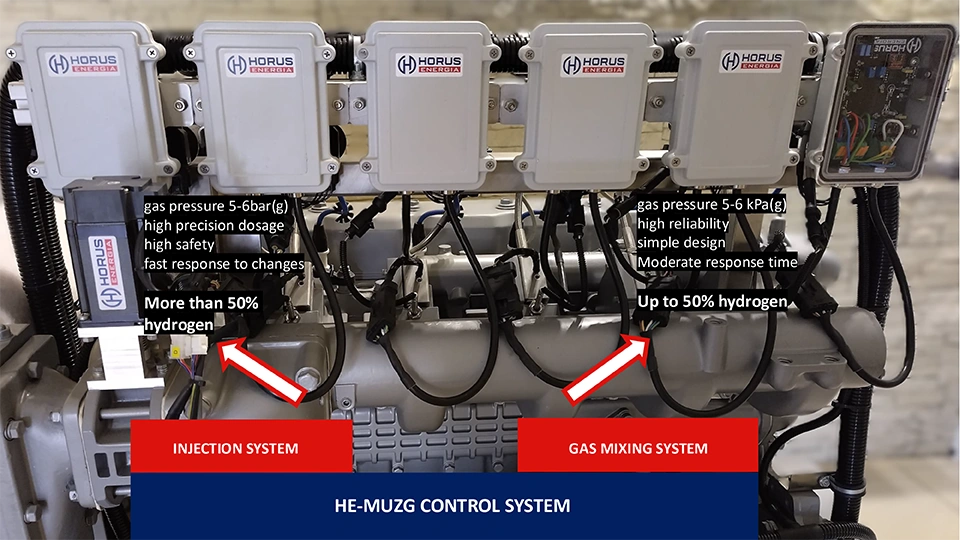

The hydrogen fuel mentioned earlier is currently driving many innovations and investments aimed at reducing the carbon footprint. In 2022, in collaboration with PGNiG S.A. (now ORLEN S.A.), we conducted a two-year intensive R&D project, resulting in a unique solution that allows a cogeneration unit to use a mixture of methane and hydrogen in any proportions. Additionally, these proportions can be adjusted from 0% to 100% during operation without reducing the unit’s current power.

Plans for the Near Future

As part of our independent research, we are working on technology adapted to other increasingly popular fuels, such as ammonia, methanol, or other synthetic fuels. Each of these fuels has its specific properties, both advantageous and challenging, which must be effectively addressed. Our long-standing experience in implementing innovative solutions and our know-how, unique among companies in our sector on the domestic market, are proving invaluable. Our goal is to enable our clients to generate electricity combined with heat in a zero-emission manner in the near future by using zero-emission fuels like green hydrogen, green ammonia, biomethane, bioalcohols, or bio-oils, while maintaining existing habits and functionalities, regardless of whether we are talking about cogeneration units for continuous operation or backup units for emergency power supply. We are currently modifying backup generator units powered by natural gas for one of our clients so that they can be powered by hydrogen fuel.

To facilitate this, we are also working intensively on the accompanying infrastructure, offering our clients hydrogen, biomethane, and bioLNG tanks, as well as hydrogen compressors, energy storage, full integration with renewable energy sources (e.g., photovoltaics), and even installations dedicated to zero-emission mobility, such as hydrogen stations, biomethane stations, or zero-emission stations for fast and ultra-fast charging of battery electric vehicles. It is worth noting that our solutions allow for local energy production, without transmission losses, long procedures, or costly investments in the expansion of power grids. The installation can be easily expanded to greater capacities as the energy demand or the investor’s business grows.

Horus-Energia presentation during Industry Meetings EXPO KATOWICE

On September 4-6, 2024, we took an active part in the EXPO KATOWICE Meeting Industry, including the EXPO KATOWICE International Fair – the largest in Poland and third in Europe for heavy industry – and the ECODom EXPO KATOWICE International Fair – dedicated to energy transition and green technologies.

A representative of our company – Mr. Slawomir Stefaniak – also took part as a speaker at the conference “Industry 5.0 – the transformational challenges of industry” in the panel “New technologies as a tool for introducing the European Green Deal”. The panel discussed modern solutions to reduce carbon footprint.

source: Horus-Energia Sp. z o.o.